Die Eleganz und Leichtigkeit einer Dosierung mit zwangsgesteuerten Ventilen, variablen Druckhub und in Voll-PTFE-Ausstattung für Flüssigkeiten und Gase.

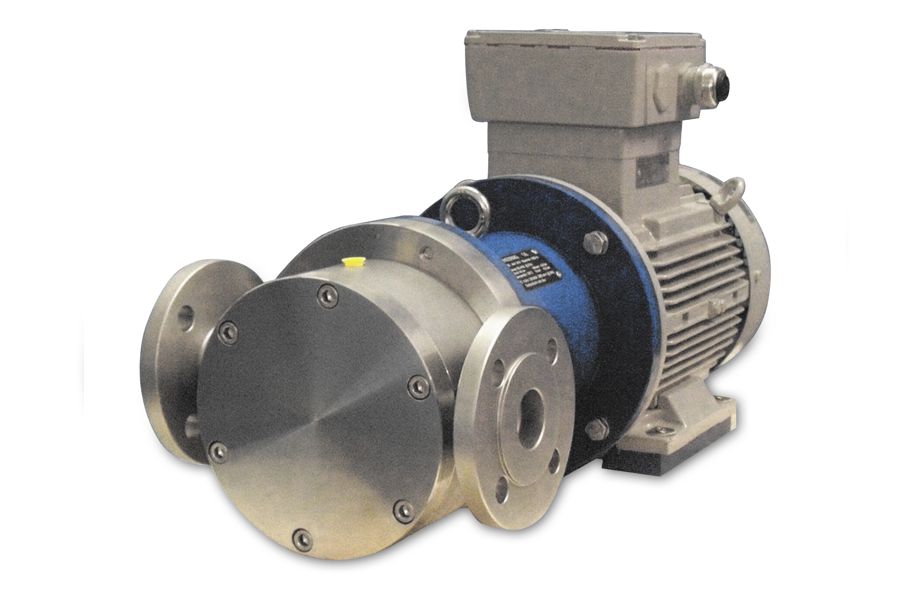

Ziclon 04 gas circulation pumps are oil-free and variable speed gas transfer pumps configurable for laboratory applications, instrument applications or for industrial applications. Their basic components are the pump housing, an asymmetrically mounted rotor and a magnetically coupled drive motor. Because all Ziclon-04 models are magnetically coupled, they are hermetically sealed and pass the helium leak test.

We design each model to your specific requirements and, on request, adapt the pump to the most demanding operating conditions: from high process temperatures up to 300°C, to system pressures up to 400 bar, to suitability in explosive environments requiring ATEX conformity. In addition, it is possible to heat the pump heads electrically, with superheated steam or heat transfer oil, or to cool them with water or refrigerants.

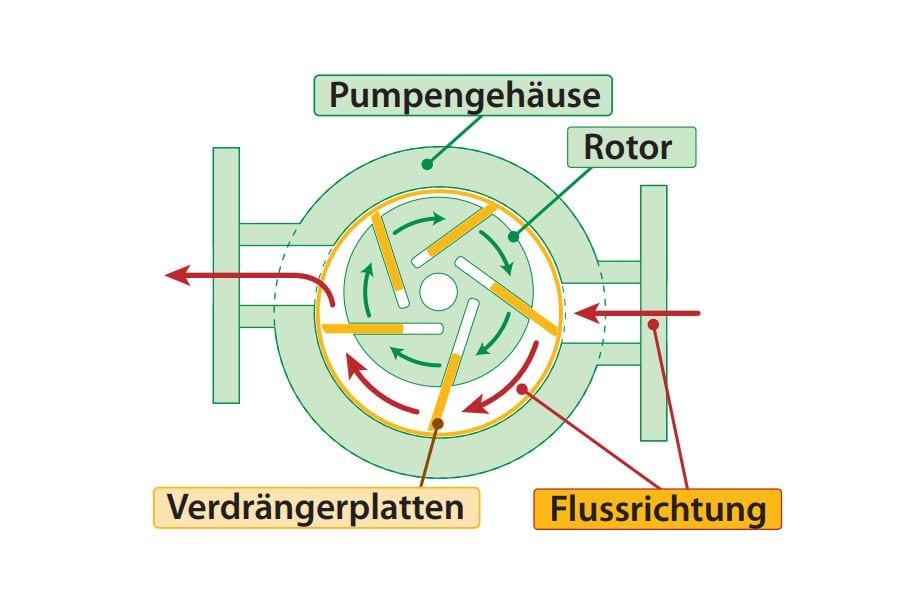

Functionality of the Ziclon 04 The rotor - also known as the slider - has three to five slots into which displacement plates - also known as sliders - are fitted. The centrifugal forces of the rotating rotor press these vanes against the housing wall, forming several conveying chambers. Since the rotor is mounted asymmetrically, as it rotates it creates an increase in volume on the suction side and thus a vacuum, which initiates the suction process. As the rotor continues to rotate, the chamber volumes shrink again and the gas is forced out to the discharge side of the pump.

The rotor - also known as the slider - has three to five slots into which displacement plates - also known as sliders - are fitted. The centrifugal forces of the rotating rotor press these vanes against the housing wall, forming several conveying chambers. Since the rotor is mounted asymmetrically, as it rotates it creates an increase in volume on the suction side and thus a vacuum, which initiates the suction process. As the rotor continues to rotate, the chamber volumes shrink again and the gas is forced out to the discharge side of the pump.

Reliable, durable, robust

Since we manufacture the pump housing of the Ziclon 04 gas circulation pump from high-quality and robust materials, it is suitable for simple gas handling tasks as well as for operation under harsh industrial conditions and for aggressive gas applications.

Depending on customer requirements and the type of application, we use various hardened stainless steels or non-toxic ceramics such as silicon carbide or tungsten carbide (hard metal). The displacement plates are made of SiC ceramic, polyetheretherketone (PEEK) or special carbon and do not require lubrication.

We also adapt the type of gas connections to your respective application and integration into the gas circulation process. Cutting ring fittings, flange connections and high-pressure fittings are available for this purpose.

Heatable up to 300°C

Heatable pump heads are necessary to implement conveying or reaction processes under high temperatures, to keep the temperature constant during the pumping process and to avoid back condensation in the pump head. The pump head can be heated electrically or by a heat transfer medium. The temperature can be set on external temperature controllers or via the flow temperature of the connected thermostat.

Coolable pump heads

Coolable pump heads enable cooled process operations and compensate for reaction and/or abrasion-related heating during the pumping operation in the pump head. The pump head can be connected to a refrigeration circuit. The temperature can be regulated via the flow temperature of the connected thermostat or cryostat. The temperature can be regulated via the supply temperature of the connected thermostat or cryostat.

Process pressures up to 400 bar

For process operations or chemical reactions that have to run under high process pressures due to the process, we can configure the Ziclon 04 gas circulator for system pressures of up to 400 bar. The maximum pressure difference of the gas circulation pump is independent of this system pressure design.

Low-wear design

If you work with processes that require maximum gas purity, minimum particle entry or particularly long service lives, a low-wear design of the Zyclon 04 makes sense. Specially hardened running surfaces, ceramic inserts, special displacement plates and a controlled speed behavior reduce the physically unavoidable abrasion.

Adapted speed behavior

Speed-controlled gas circulators can be networked with external frequency converters for variable, speed-adjusted pumping behavior or equipped with a frequency converter mounted on the drive motor. The functionality of the frequency inverter allows you to influence the start-up behavior of the pump (soft start), vary the flow rate, reduce pumping wear, or achieve energy-efficient operation.

ATEX compliant design

An ATEX-compliant Ziclon 04 is required in order to be allowed to pump gases in potentially explosive operating sites. When designing the drive motor and pump head, we use the ATEX regulations of the respective explosion protection zone of the operating site as a guideline. The Ex-certified motors with required temperature monitoring that we use are sourced exclusively from market-leading motor suppliers.

Please note that as a special pump manufacturer, we cannot issue ATEX certification for our pumps. However, we certify with the delivery of each pump its ATEX conformity.

Heatable up to 300°C

Heatable pump heads are necessary to implement conveying or reaction processes under high temperatures, to keep the temperature constant during the pumping process and to avoid back condensation in the pump head. The pump head can be heated electrically or by a heat transfer medium. The temperature can be set on external temperature controllers or via the flow temperature of the connected thermostat.

Coolable pump heads

Coolable pump heads enable cooled process operations and compensate for reaction and/or abrasion-related heating during the pumping operation in the pump head. The pump head can be connected to a refrigeration circuit. The temperature can be regulated via the flow temperature of the connected thermostat or cryostat. The temperature can be regulated via the supply temperature of the connected thermostat or cryostat.

Process pressures up to 400 bar

For process operations or chemical reactions that have to run under high process pressures due to the process, we can configure the Ziclon 04 gas circulator for system pressures of up to 400 bar. The maximum pressure difference of the gas circulation pump is independent of this system pressure design.

Low-wear design

If you work with processes that require maximum gas purity, minimum particle entry or particularly long service lives, a low-wear design of the Zyclon 04 makes sense. Specially hardened running surfaces, ceramic inserts, special displacement plates and a controlled speed behavior reduce the physically unavoidable abrasion.

Adapted speed behavior

Speed-controlled gas circulators can be networked with external frequency converters for variable, speed-adjusted pumping behavior or equipped with a frequency converter mounted on the drive motor. The functionality of the frequency inverter allows you to influence the start-up behavior of the pump (soft start), vary the flow rate, reduce pumping wear, or achieve energy-efficient operation.

ATEX compliant design

An ATEX-compliant Ziclon 04 is required in order to be allowed to pump gases in potentially explosive operating sites. When designing the drive motor and pump head, we use the ATEX regulations of the respective explosion protection zone of the operating site as a guideline. The Ex-certified motors with required temperature monitoring that we use are sourced exclusively from market-leading motor suppliers.

Please note that as a special pump manufacturer, we cannot issue ATEX certification for our pumps. However, we certify with the delivery of each pump its ATEX conformity.

Zyklon Z04

| Dimensions | 270 × 130 × 205 cm |

|---|---|

| Ausstattung | heatable, Master/Slave, Mehrkanal, Mischpumpen, Sampling pumps, pulsfrei, temperature-controlled |

| ATEX | |

| physical state |