Die Eleganz und Leichtigkeit einer Dosierung mit zwangsgesteuerten Ventilen, variablen Druckhub und in Voll-PTFE-Ausstattung für Flüssigkeiten und Gase.

The classic peripheral impeller pumps of the Flujo 01 series essentially consist of a pump head with delivery channel and breaker bar, a peripheral impeller and a magnetically coupled drive motor. Because all Flujo 01 pumps are manufactured in a magnetically coupled design, they are hermetically sealed and meet the environmental requirements of TA-Luft.

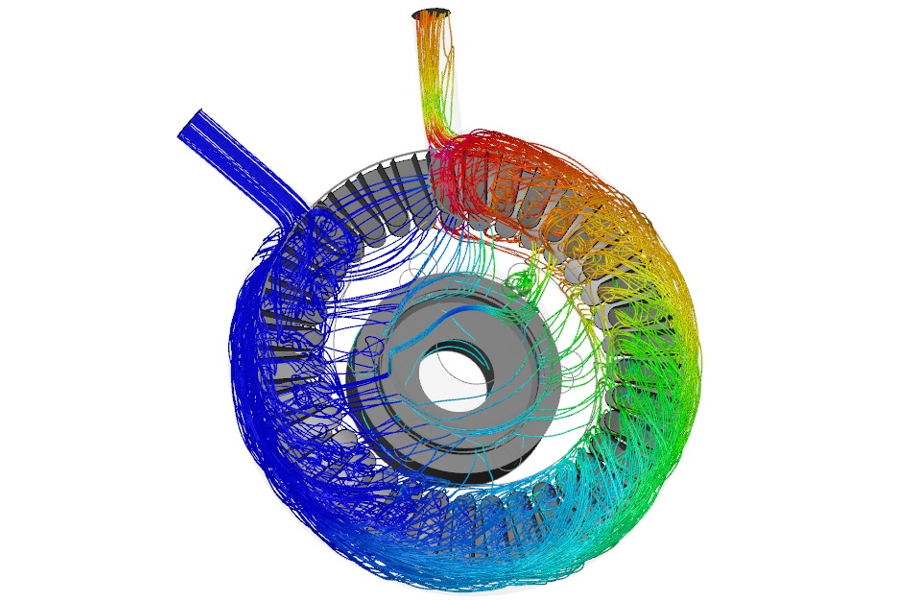

The peripheral impeller is equipped with conveying cells, the number and design of which we adapt to your application. The rotation of the impeller causes the pressure in these conveying cells to rise rapidly, so that the exchange of momentum between the impeller and the conveying channel, as well as backflows due to pressure equalization within the pump head, intensively swirl the pumped medium.

Since the characteristic curve of peripheral gear pumps is almost linear as the flow rate decreases, the flow rate can be easily adjusted using a frequency converter. This is ideal for applications with low flow rates and relatively high delivery pressures. The Flujo 01 is suitable in research, process development and small-volume production for pumping aggressive acids, alkalis, solvents or liquids with high gas contents. However, we also adapt it for high-pressure processes and processes with hot fluids.

The flow rates can also be tailored to the requirements of your individual project: from laboratory scale with small flow rates to production scale. Upscaling is easily possible to transfer the results from laboratory tests directly to production.

All models of the Flujo 01 series are also available in customer specific versions available; including for process temperatures up to 450°C, system pressures up to 700 bar, and ATEX-compliant for operation in Zone 1 hazardous areas.

Robust and versatile

The materials used in the Flujo 01 withstand harsh operating conditions, aggressive fluid properties, and high gas contents in liquids. For the pump housings, we use various stainless steels, Hastelloy®, ceramics and non-oxide ceramics such as silicon carbide or tungsten carbide, as well as PTFE linings. O-rings made of FKM, FFKM (including Dupont™Kalrez©) or high-temperature resistant graphite seals serve as seals. Fluid connections can be implemented as stainless steel or PTFE/PFA compression fittings, flanged connections, and high-pressure fittings. The selection of connections depends on the respective application and integration of the pumps into the process.

Its tolerance to solids and gases makes the Flujo 01 peripheral gear pumps an interesting alternative to gear pumps, peristaltic pumps or other small delivery pumps. Thanks to its hermetically sealed magnetically coupled design, it enables emission-free handling of aggressive fluids as well as environmentally hazardous substances and meets the requirements of TA-Luft.

If your process has special requirements for the design, materials or performance of the peripheral impeller pump, we can tailor the material selection and pump head design of the Flujo 01 to your individual needs.

The application-specific special versions are all based on the basic design of the Flujo 01. They are also magnetically coupled and hermetically sealed. The following extensions and adaptations are possible.

Flujo Lab

This special design in compact construction is a variable speed small feed pump capable of automation for a wide variety of feed tasks in the laboratory, process development and for equipment applications. The installation of a separate frequency converter is not required. With this system solution you save space, installation effort and investment costs.

The Flujo Lab can be controlled both directly on the backlit touch panel and via an external interface. A 4-20 mA interface and a digital RS232 interface are available.

Heated flujo 01

If high process temperatures are required due to the process - for example when conveying hot fluids - or if the temperature is to be kept constant during the process, we equip the Flujo 01 peripheral gear pump with a heatable pump head. The simple design contains a heat transfer medium circuit between a thermostat or superheated steam connection and the heating chamber incorporated in the pump head.

For example, in order to avoid crystallization in fluids with a low melting point in the flow-reduced containment can area, the Flujo 01 in the extended version is equipped with a heatable containment can in addition to a heatable pump head. In this case, the pump is equipped with a double containment can design. Furthermore, it is possible to heat the pump head electrically.

Für den Hochtemperatur-Betrieb bis 450°C optimierte Flujo 01

Bei sehr hohen Prozesstemperaturen machen sich die extrem unterschiedlichen Wärmeausdehnungskoeffizienten der zum Einsatz kommenden Werkstoffe und die Temperaturabhängigkeit der Antriebsmagnete bemerkbar. Flujo-01-Modelle für Hochtemperaturprozesse konzipieren wir deshalb für jede Anwendung individuell – in Spezialfällen sind die Peripheralradpumpen für Fluidtemperaturen bis 450°C ausgelegt.

Beheizbare Pumpenköpfe, separat beheizbare Lagergehäuse, entkoppelte, zum Teil kühlbare Antriebslaternen, separate Spalttopfspülungen oder auch spezielle Betriebsweisen machen die Konstruktion dieser Pumpen zu einer sehr komplexen Aufgabe.

Coolable Flujo 01

Coolable pump heads maintain, among other things, fluid temperatures required by the process, dissipate heat generated during exothermic processes, and prevent outgassing effects and cavitation. In a simple design, a coolant circuit is established between a cryostat or a cold water connection and the cooling chamber incorporated in the pump head.

In an extended version, not only the pump head but also the containment can can be cooled. In this case, the pump is designed as a double containment can. This design is useful to limit or avoid heat generation in the containment can area during pumping of low boiling point fluids, which is generated by the magnetic pump drive.

Corrosion resistant Flujo 01

Corrosion-resistant F01 peripheral gear pumps are used when pumping particularly aggressive fluids requires the highest chemical resistance. For this purpose, we equip the stainless steel housing and the flange connections of the peripheral gear pump with solid PTFE inliners. Pump rotor and the containment can are also lined with PTFE or manufactured in a PTFE-carbon version. For the pump shaft, we use a silicon carbide or tungsten carbide ceramic.

Suitable for high pressure

If you want to use the Flujo 01 peripheral gear pump for processes with high system pressures, we will calculate and design the necessary layout for your specific application. We can make it suitable for pressures up to a maximum of 750 bar.

In this special adaptation, we take into account the particular challenges of high system pressures: The containment can must meet the requirements of the Pressure Vessel Ordinance and must not seriously restrict the transmission of the magnetic drive forces. In addition, we have to keep heat generation due to eddy current losses as low as possible.

The required pressure build-up between pump inlet and outlet (dp) is independent of the system pressure design of the pump. The pressure difference between pump inlet and outlet is based exclusively on the assigned characteristic curve.

Multiphase pump

Designed as a multiphase pump, the Flujo 01 can handle high gas contents in the fluid - an additional benefit of the peripheral impeller principle. With special impeller geometries, it can handle gas contents in the fluid of up to 50 percent by volume in individual cases.

In this version, the Flujo 01 is particularly suitable for pumping fluids with a low boiling point, for discharge processes in distillation plants, for pumping liquids with dissolved gas contents or liquid-gas mixtures. In water and wastewater treatment, multiphase pumps are used in gassing flotation or denitrification.

Adapted speed behavior

On request, we can network the Flujo 01 with external frequency converters or install a frequency converter on the drive motor. With the help of this, the start-up behavior of the pump (soft start), the setting of the specific operating point, process-dependent flow rates or even energy-efficient operation can be controlled.

ATEX compliant Flujo 01

In order to make the Flujo 01 suitable for operation in potentially explosive atmospheres of zones 1 and 2, we take into account the respective Ex classification of the operating site according to ATEX regulations in the design of the pump and all pump-relevant components and in the overall design. The Ex-certified motors with required temperature monitoring that we use come exclusively from market-leading motor suppliers.

Frequency converters are usually removed from the hazardous area. If, in individual cases, a solution with a frequency converter permanently installed on the motor is desired, please contact us so that we can implement your special requirements.

Please note that as a special pump manufacturer, we cannot issue ATEX certification on our pumps. However, we certify with the delivery of each pump its ATEX conformity.

Inline peripheral gear pump

When designing the Flujo 01 as an inline peripheral impeller pump, we conceive the delivery channel with interrupter bar, the impeller and the flange connections in such a way that they can be integrated "inline" into the delivery process. The flange connections of the inline version can be integrated into both a vertical and a horizontal pipeline run.

Falls Ihr Prozess besondere Anforderungen an Bauweise, Materialien oder Leistungsfähigkeit der Peripheralradpumpe stellt, können wir die Werkstoffauswahl und Pumpenkopfauslegung der Flujo 01 an Ihren individuellen Bedürfnisse orientieren. Die anwendungsspezifischen Sonderausführungen basieren alle auf dem prinzipiellen Aufbau der Flujo 01. Sie sind ebenfalls magnetgekuppelt und hermetisch dicht. Folgende Erweiterungen und Anpassungen sind möglich.

Flujo Lab

This special design in compact construction is a variable speed small feed pump capable of automation for a wide variety of feed tasks in the laboratory, process development and for equipment applications. The installation of a separate frequency converter is not required. With this system solution you save space, installation effort and investment costs.

The Flujo Lab can be controlled both directly on the backlit touch panel and via an external interface. A 4-20 mA interface and a digital RS232 interface are available.

Heated flujo 01

If high process temperatures are required due to the process - for example when conveying hot fluids - or if the temperature is to be kept constant during the process, we equip the Flujo 01 peripheral gear pump with a heatable pump head. The simple design contains a heat transfer medium circuit between a thermostat or superheated steam connection and the heating chamber incorporated in the pump head.

For example, in order to avoid crystallization in fluids with a low melting point in the flow-reduced containment can area, the Flujo 01 in the extended version is equipped with a heatable containment can in addition to a heatable pump head. In this case, the pump is equipped with a double containment can design. Furthermore, it is possible to heat the pump head electrically.

Für den Hochtemperatur-Betrieb bis 450°C optimierte Flujo 01

Bei sehr hohen Prozesstemperaturen machen sich die extrem unterschiedlichen Wärmeausdehnungskoeffizienten der zum Einsatz kommenden Werkstoffe und die Temperaturabhängigkeit der Antriebsmagnete bemerkbar. Flujo-01-Modelle für Hochtemperaturprozesse konzipieren wir deshalb für jede Anwendung individuell – in Spezialfällen sind die Peripheralradpumpen für Fluidtemperaturen bis 450°C ausgelegt.

Beheizbare Pumpenköpfe, separat beheizbare Lagergehäuse, entkoppelte, zum Teil kühlbare Antriebslaternen, separate Spalttopfspülungen oder auch spezielle Betriebsweisen machen die Konstruktion dieser Pumpen zu einer sehr komplexen Aufgabe.

Coolable Flujo 01

Coolable pump heads maintain, among other things, fluid temperatures required by the process, dissipate heat generated during exothermic processes, and prevent outgassing effects and cavitation. In a simple design, a coolant circuit is established between a cryostat or a cold water connection and the cooling chamber incorporated in the pump head.

In an extended version, not only the pump head but also the containment can can be cooled. In this case, the pump is designed as a double containment can. This design is useful to limit or avoid heat generation in the containment can area during pumping of low boiling point fluids, which is generated by the magnetic pump drive.

Corrosion resistant Flujo 01

Corrosion-resistant F01 peripheral gear pumps are used when pumping particularly aggressive fluids requires the highest chemical resistance. For this purpose, we equip the stainless steel housing and the flange connections of the peripheral gear pump with solid PTFE inliners. Pump rotor and the containment can are also lined with PTFE or manufactured in a PTFE-carbon version. For the pump shaft, we use a silicon carbide or tungsten carbide ceramic.

Suitable for high pressure

If you want to use the Flujo 01 peripheral gear pump for processes with high system pressures, we will calculate and design the necessary layout for your specific application. We can make it suitable for pressures up to a maximum of 750 bar.

In this special adaptation, we take into account the particular challenges of high system pressures: The containment can must meet the requirements of the Pressure Vessel Ordinance and must not seriously restrict the transmission of the magnetic drive forces. In addition, we have to keep heat generation due to eddy current losses as low as possible.

The required pressure build-up between pump inlet and outlet (dp) is independent of the system pressure design of the pump. The pressure difference between pump inlet and outlet is based exclusively on the assigned characteristic curve.

Multiphase pump

Designed as a multiphase pump, the Flujo 01 can handle high gas contents in the fluid - an additional benefit of the peripheral impeller principle. With special impeller geometries, it can handle gas contents in the fluid of up to 50 percent by volume in individual cases.

In this version, the Flujo 01 is particularly suitable for pumping fluids with a low boiling point, for discharge processes in distillation plants, for pumping liquids with dissolved gas contents or liquid-gas mixtures. In water and wastewater treatment, multiphase pumps are used in gassing flotation or denitrification.

Adapted speed behavior

On request, we can network the Flujo 01 with external frequency converters or install a frequency converter on the drive motor. With the help of this, the start-up behavior of the pump (soft start), the setting of the specific operating point, process-dependent flow rates or even energy-efficient operation can be controlled.

ATEX compliant Flujo 01

In order to make the Flujo 01 suitable for operation in potentially explosive atmospheres of zones 1 and 2, we take into account the respective Ex classification of the operating site according to ATEX regulations in the design of the pump and all pump-relevant components and in the overall design. The Ex-certified motors with required temperature monitoring that we use come exclusively from market-leading motor suppliers.

Frequency converters are usually removed from the hazardous area. If, in individual cases, a solution with a frequency converter permanently installed on the motor is desired, please contact us so that we can implement your special requirements.

Please note that as a special pump manufacturer, we cannot issue ATEX certification on our pumps. However, we certify with the delivery of each pump its ATEX conformity.

Inline peripheral gear pump

When designing the Flujo 01 as an inline peripheral impeller pump, we conceive the delivery channel with interrupter bar, the impeller and the flange connections in such a way that they can be integrated "inline" into the delivery process. The flange connections of the inline version can be integrated into both a vertical and a horizontal pipeline run.

Flujo F01

| Dimensions | 270 × 130 × 205 cm |

|---|---|

| Ausstattung | heatable, Master/Slave, Mehrkanal, Mischpumpen, Sampling pumps, pulsfrei, temperature-controlled |

| ATEX | |

| physical state |