Die Eleganz und Leichtigkeit einer Dosierung mit zwangsgesteuerten Ventilen, variablen Druckhub und in Voll-PTFE-Ausstattung für Flüssigkeiten und Gase.

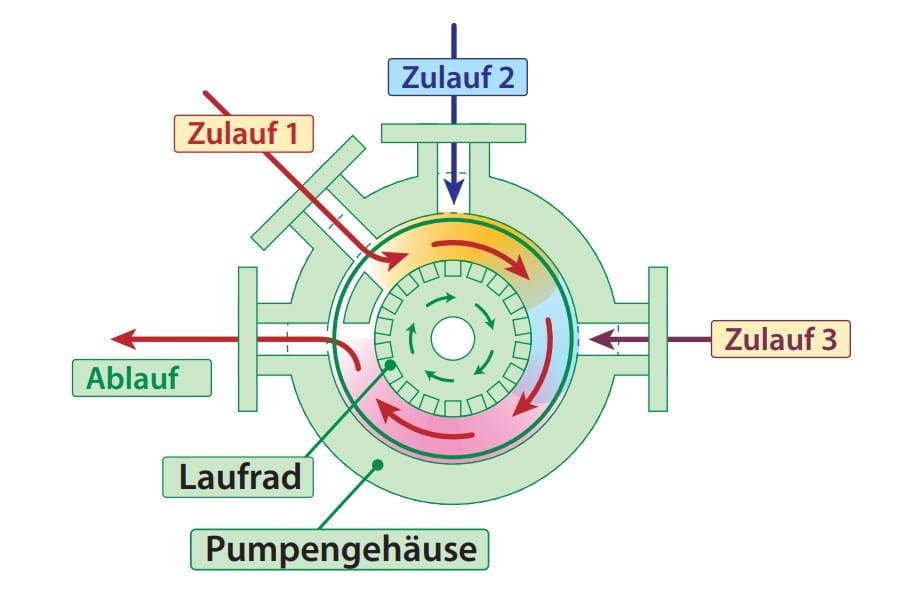

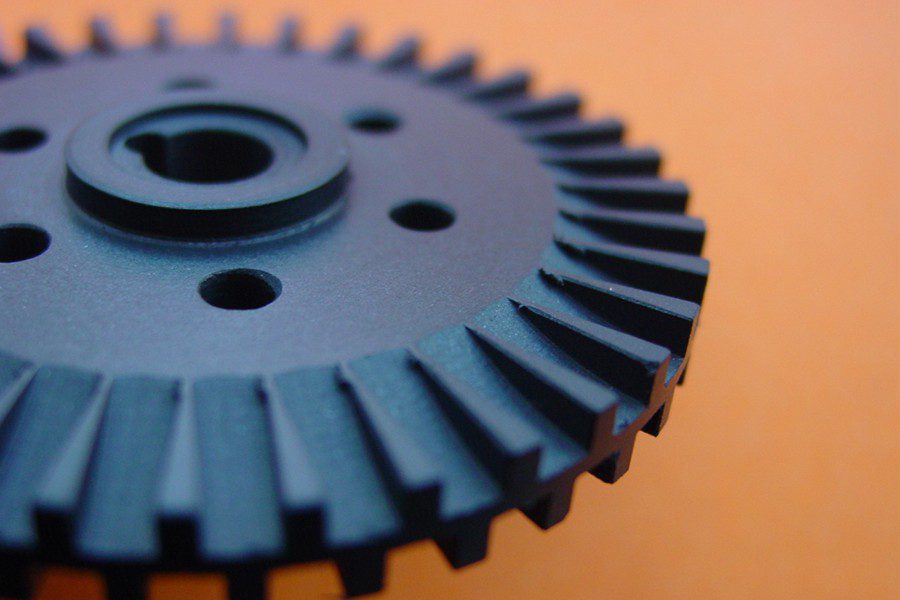

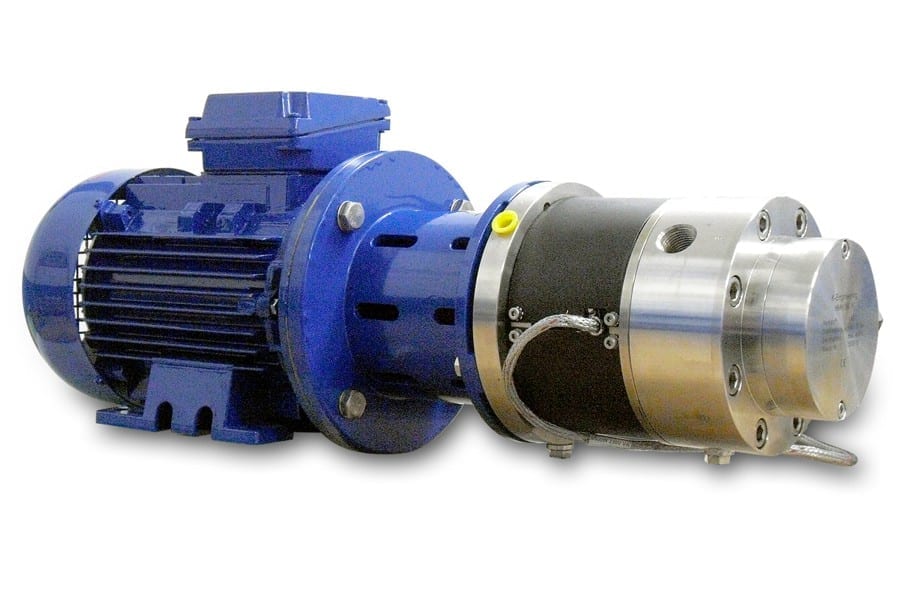

The pumps of series Espira E02 are a magnetically coupled special form of the peripheral impeller pumps . These pumps, which we developed in cooperation with BASF, take advantage of the characteristic properties of the peripheral impeller pump: The rotation of the impeller causes the pressure in the peripheral delivery cells to rise rapidly. The exchange of momentum between the impeller and the delivery channel, as well as reverse flows due to a pressure equalization within the pump head, cause intensive turbulence of the pumped medium. This enables intensive mixing and homogenization processes within the pump head during the conveying process.

This makes Espira-02 pumps ideal for demanding mixing, dilution and homogenization applications in laboratory, process development and small-scale production. They are used in many processes as an effective and economical alternative to stirred tanks, rotor-stator mixers, injectors and static mixers.

Multiple fluid ports on the inlet side can feed two or more components directly into the pump head, which may be liquid, gas, or solids-laden. Since peripheral impeller pumps are self-priming, there is basically no need for feed pumps; in individual cases, however, they can still be useful for establishing a precise stoichiometric ratio.

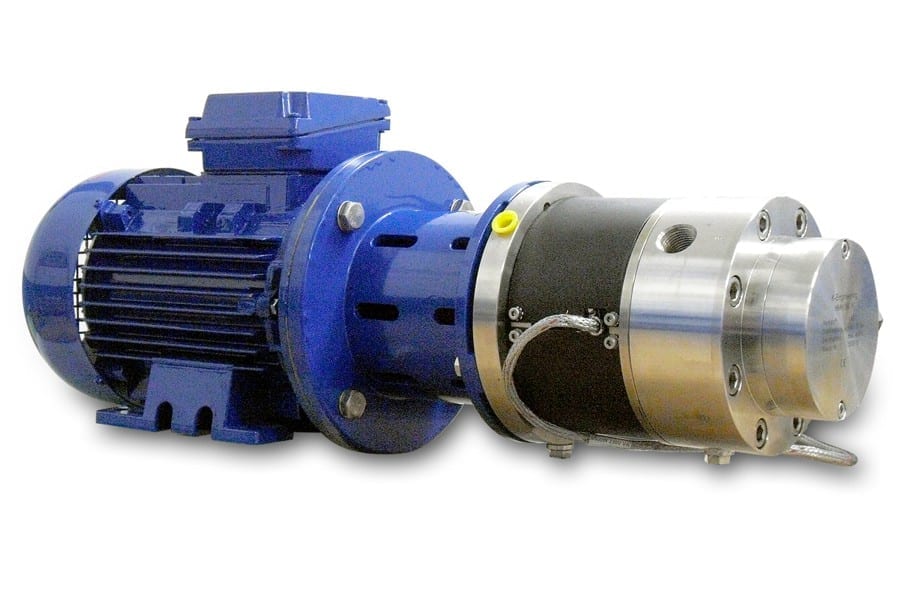

The Espira-02 series is always equipped with a magnetic coupling and therefore does not require a dynamically loaded seal. All models are therefore hermetically sealed and meet the environmental requirements according to TA-Luft.

We manufacture them according to the individual customer requirements for different flow rates: from laboratory scale with correspondingly small flow rates up to the production plant. Up-scaling is possible without any problems in order to transfer the results from the laboratory tests to production.

All models of the Espira E02 series are also available in customer specific versions available; among others for process temperatures up to 450°C, system pressures up to 700 bar as well as ATEX compliant for operation in zone 1 hazardous areas.

High quality and resistant materials

The Espira-02 models are designed for harsh operating conditions, aggressive fluid properties as well as high gas contents in the fluid. For the pump housings, we use various stainless steels, Hastelloy®, ceramics and non-oxide ceramics such as silicon carbide or tungsten carbide, as well as PTFE linings. Static sealing is provided by O-rings made of FKM, FFKM (from Kalrez© and DuPont©, among others) or high-temperature resistant graphite seals.

We select the type of fluid connections depending on the particular application and integration of the pumps into the process. Stainless steel or PTFE/PFA compression fittings, flange connections or high pressure fittings are available.

Wide range of applications

Thanks to their hermetically sealed, magnetically coupled design, the Espira 02 enables emission-free handling of aggressive fluids and environmentally hazardous substances. They meet the requirements of the TA-Luft. The pump is suitable for, among other things:

Espira Lab

We can adapt the drive and pump control of the small mixers or small reactors specifically to the conditions of your particular laboratory application.

Drive and pump control are accommodated in a compact housing and can be conveniently operated via touchscreen. Speed presetting or even speed control can be regulated, as can internal volume flow control with a separate flow meter. This saves time, space, installation effort and investment costs. In addition to the backlit touch panel for operation directly on the pump, external interfaces are also available.

Heated Espira 02

If high process temperatures are required due to the process or if reaction processes with solidification-critical melts and the risk of crystallization are to be carried out, we integrate pump heads that can be heated up to 300°C. The pump heads can be equipped with a heating chamber. In a simple design, they contain a heat transfer medium circuit between a thermostat or superheated steam connection and the heating chamber incorporated in the pump head.

If reaction conversions in the flow-reduced containment can area involve the risk of crystallization or outgassing, we can also include the containment can in the heat transfer fluid circuit. In this case, the Espira 02 receives a double containment design.

Electrical heating of the pump head is also possible; for example, for processes that require preheating of the pump head or for maintaining a defined reaction temperature.

Espira 02 optimized for high-temperature operation up to 450°C

Models that are to be used at very high process temperatures are designed individually for each application.

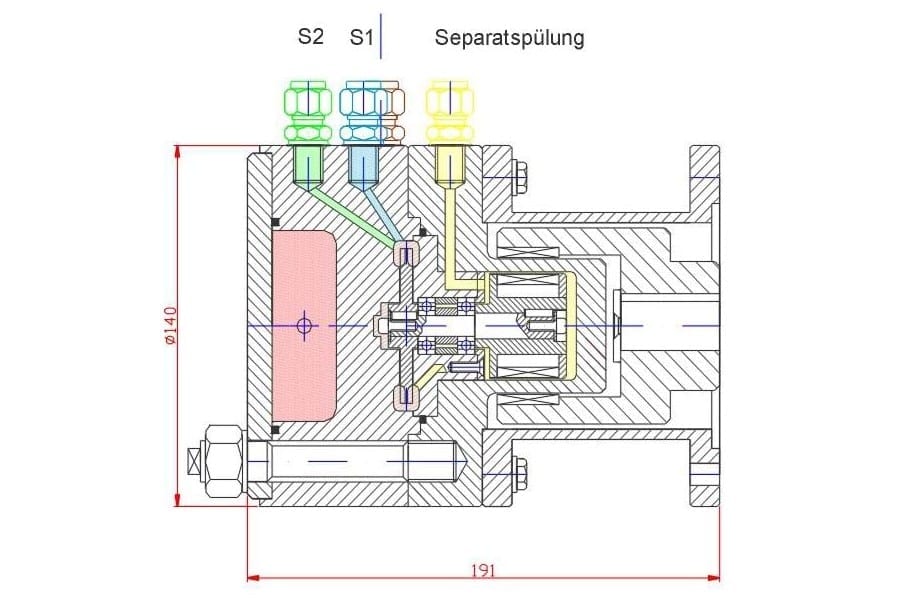

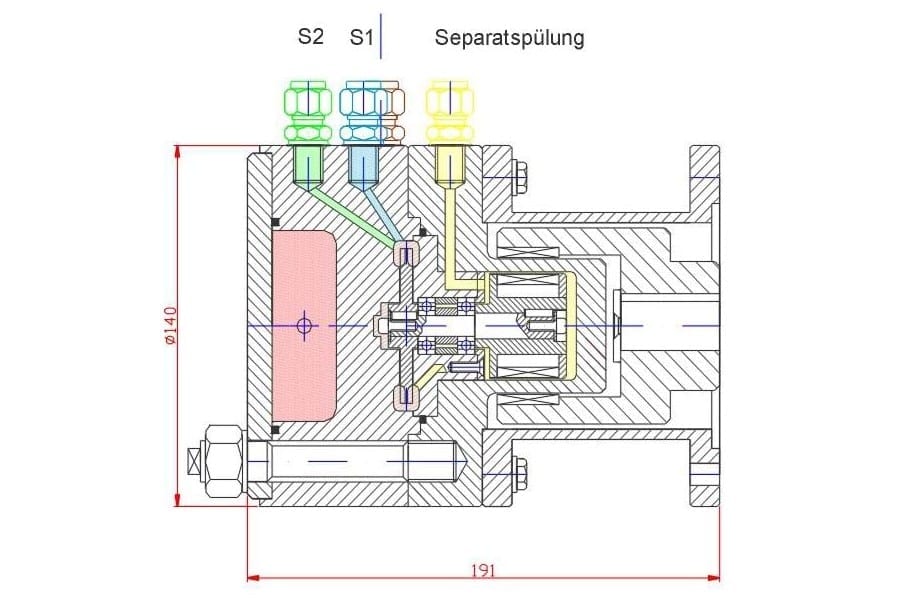

When adapting to high process temperatures, the different coefficients of thermal expansion of the materials used and the temperature dependence of the drive magnets must be taken into account in particular. Heatable pump heads, separately heatable bearing housings, decoupled and coolable drive lanterns, separate containment can flushing or special modes of operation make the design of these mixing pumps a very complex task.

Coolable Espira 02

Among other things, coolable pump heads keep fluid temperatures constant that are required by the process, dissipate heat during exothermic mixing or dilution processes, and prevent outgassing effects and cavitation.

In the simple version, a coolant circuit is established between a cryostat or a cold water connection and the cooling chamber integrated in the pump head. The extended version also includes the containment can in the coolant circuit.

High-pressure capable Espira 02

For reactions under high system pressures or with massive pressure development, we design the Espira 02 for up to 750 bar.

During design, we ensure that the containment can meets the requirements of the Pressure Vessel Ordinance, that the transmission of magnetic drive forces is not seriously restricted, and that heat generation due to eddy current losses remains low.

The required pressure build-up between pump inlet and outlet (dp) is independent of the system pressure design of the pump. The pressure difference between the pump inlet and outlet is based exclusively on the assigned characteristic curve of the mixing pump.

Espira 02 as liquid-gas reactor, multiphase or white-water pump

As a multiphase mixer, the Espira 02 exploits the peripheral impeller principle. Thanks to it, high gas contents in the fluid can be absorbed and extremely finely distributed.

Fluids and gases can therefore be mixed simultaneously during the conveying process and gases can be finely dispersed into liquids. Thanks to tailor-made impeller geometries, the Espira 02 multiphase mixers can mix all gas components of up to 50 percent by volume into the fluid, convey them as well and bring them to a liquid-gas reaction.

ATEX-compliant Espira E02 for use in potentially explosive atmospheres of zones 1 and 2

We design all pump-relevant components and their overall conception to form an explosion-proof pump, taking into account the respective Ex classification of the operating site according to ATEX regulations. The Ex-certified motors with required temperature monitoring that we use come exclusively from market-leading motor suppliers.

As a rule, frequency converters are removed from the potentially explosive plant. If, in individual cases, a solution with a frequency inverter permanently installed on the motor is required, please contact us so that we can implement your application.

Please note that as a special pump manufacturer we cannot supply ATEX certification on our pumps. However, we issue ATEX conformity with the delivery of each pump.

Corrosion resistant Espira E02

For maximum chemical resistance, we equip stainless steel housings and flange connections of the corrosion-resistant models with solid PTFE inliners. The pump rotor and containment can are also lined with PTFE or manufactured in PTFE-carbon design. The pump shaft is made of a silicon carbide or tungsten carbide ceramic.

Espira Lab

Espira Lab

We can adapt the drive and pump control of the small mixers or small reactors specifically to the conditions of your particular laboratory application.

Drive and pump control are accommodated in a compact housing and can be conveniently operated via touchscreen. Speed presetting or even speed control can be regulated, as can internal volume flow control with a separate flow meter. This saves time, space, installation effort and investment costs. In addition to the backlit touch panel for operation directly on the pump, external interfaces are also available.

Heated Espira 02

If high process temperatures are required due to the process or if reaction processes with solidification-critical melts and the risk of crystallization are to be carried out, we integrate pump heads that can be heated up to 300°C. The pump heads can be equipped with a heating chamber. In a simple design, they contain a heat transfer medium circuit between a thermostat or superheated steam connection and the heating chamber incorporated in the pump head.

If reaction conversions in the flow-reduced containment can area involve the risk of crystallization or outgassing, we can also include the containment can in the heat transfer fluid circuit. In this case, the Espira 02 receives a double containment design.

Electrical heating of the pump head is also possible; for example, for processes that require preheating of the pump head or for maintaining a defined reaction temperature.

Espira 02 optimized for high-temperature operation up to 450°C

Models that are to be used at very high process temperatures are designed individually for each application.

When adapting to high process temperatures, the different coefficients of thermal expansion of the materials used and the temperature dependence of the drive magnets must be taken into account in particular. Heatable pump heads, separately heatable bearing housings, decoupled and coolable drive lanterns, separate containment can flushing or special modes of operation make the design of these mixing pumps a very complex task.

Coolable Espira 02

Coolable Espira 02

Among other things, coolable pump heads keep fluid temperatures constant that are required by the process, dissipate heat during exothermic mixing or dilution processes, and prevent outgassing effects and cavitation.

In the simple version, a coolant circuit is established between a cryostat or a cold water connection and the cooling chamber integrated in the pump head. The extended version also includes the containment can in the coolant circuit.

High-pressure capable Espira 02

For reactions under high system pressures or with massive pressure development, we design the Espira 02 for up to 750 bar.

During design, we ensure that the containment can meets the requirements of the Pressure Vessel Ordinance, that the transmission of magnetic drive forces is not seriously restricted, and that heat generation due to eddy current losses remains low.

The required pressure build-up between pump inlet and outlet (dp) is independent of the system pressure design of the pump. The pressure difference between the pump inlet and outlet is based exclusively on the assigned characteristic curve of the mixing pump.

Espira 02 as liquid-gas reactor, multiphase or white-water pump

As a multiphase mixer, the Espira 02 exploits the peripheral impeller principle. Thanks to it, high gas contents in the fluid can be absorbed and extremely finely distributed.

Fluids and gases can therefore be mixed simultaneously during the conveying process and gases can be finely dispersed into liquids. Thanks to tailor-made impeller geometries, the Espira 02 multiphase mixers can mix all gas components of up to 50 percent by volume into the fluid, convey them as well and bring them to a liquid-gas reaction.

ATEX-compliant Espira E02 for use in potentially explosive atmospheres of zones 1 and 2

We design all pump-relevant components and their overall conception to form an explosion-proof pump, taking into account the respective Ex classification of the operating site according to ATEX regulations. The Ex-certified motors with required temperature monitoring that we use come exclusively from market-leading motor suppliers.

As a rule, frequency converters are removed from the potentially explosive plant. If, in individual cases, a solution with a frequency inverter permanently installed on the motor is required, please contact us so that we can implement your application.

Please note that as a special pump manufacturer we cannot supply ATEX certification on our pumps. However, we issue ATEX conformity with the delivery of each pump.

Corrosion resistant Espira E02

For maximum chemical resistance, we equip stainless steel housings and flange connections of the corrosion-resistant models with solid PTFE inliners. The pump rotor and containment can are also lined with PTFE or manufactured in PTFE-carbon design. The pump shaft is made of a silicon carbide or tungsten carbide ceramic.

Espira E02

| Dimensions | 270 × 130 × 205 cm |

|---|---|

| Ausstattung | heatable, Master/Slave, Mehrkanal, Mischpumpen, Sampling pumps, pulsfrei, temperature-controlled |

| ATEX | |

| physical state |